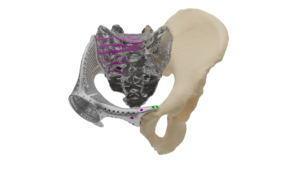

Reconstruction of Right Hemipelvis with a Customized Implant Solution

Patient Overview:

A 52-year-old male patient was diagnosed with a tumor in the right pelvis, significantly affecting the iliac bone. Due to the extent of bone involvement, surgical resection was deemed necessary to remove the tumor-affected bone entirely. However, this created a major structural deficit, requiring a comprehensive reconstructive solution to restore pelvic integrity, hip joint function, and overall mobility.

Under the expert guidance of Dr. Subhash Jangid, a patient-specific 3D-printed hemipelvis implant was designed to replace the resected right pelvis. Dr. Subhash Jangid played a pivotal role in ensuring the implant achieved both anatomical precision and biomechanical stability, leading to an optimal surgical outcome.

Customized Implant Design & Solution

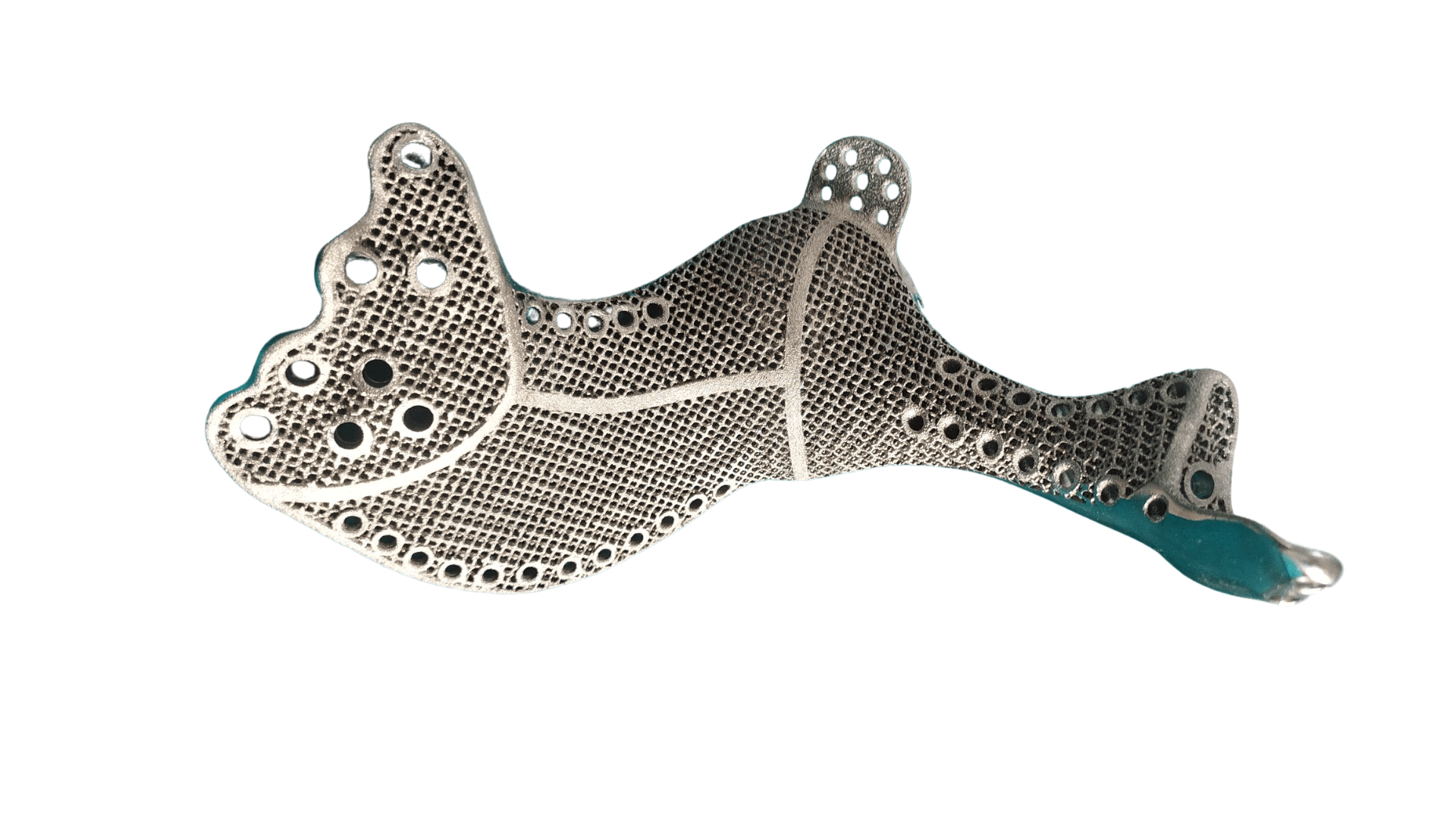

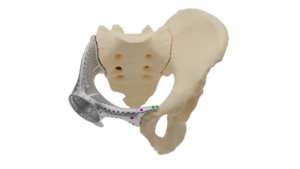

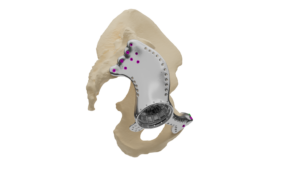

The design of the custom hemipelvis implant was meticulously developed to provide a functional and durable reconstruction, incorporating several advanced features:

- Acetabulum socket: A precisely contoured socket was integrated into the implant to restore the natural articulation of the hip joint, allowing for mobility and weight-bearing function.

- Locking screw fixation: Strategically placed locking screws ensured rigid fixation of the implant to the sacrum and the contralateral pubis bone, enhancing overall stability and load distribution. Screws planned in the sacrum were such that they should not interfere with sensitive sacral nerves.

- Lattice porous structure: The implant featured a lattice framework, designed to promote bone integration and long-term biological fixation, reducing the risk of implant loosening over time. lattice structure also reduces the overall weight of implant which was 380 gm.

- Multiple suture holes: Dedicated suture holes were incorporated to facilitate the secure attachment of ligaments and muscles, particularly in the iliac region, preserving biomechanical function.

- Polished surface: A polished surface was given to prevent wear and damage to the ligament.

Using state-of-the-art metal 3D printing technology, the implant was manufactured in biocompatible titanium grade 5, offering high strength, corrosion resistance, and optimal osteointegration properties.

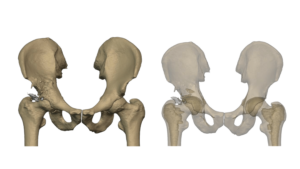

Additionally, 3D bone models of the sacrum and contralateral pelvis were provided to assist the surgical team in preoperative planning and precise intraoperative positioning.

Surgical Outcome

The surgery was performed successfully, with the implant achieving a precise anatomical fit within the patient’s body. The customized solution not only restored pelvic structure and hip joint functionality but also provided the necessary stability for rehabilitation and future mobility.

Postoperative assessments confirmed optimal implant positioning, secure fixation, and a favorable recovery trajectory, demonstrating the transformative potential of customized 3D-printed implants in complex orthopedic reconstructions.

This case perfectly highlights the efficacy of a patient-specific 3D-printed hemipelvis implant in achieving optimal anatomical restoration, biomechanical stability, and long-term osteointegration for enhanced functional recovery.