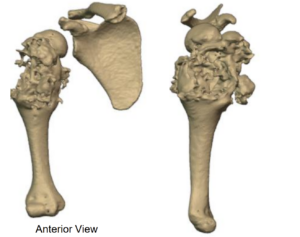

Precision Reconstruction of Humerus with Customized Implant Solution

Patient Overview

A 10-year-old boy presented with a tumor in the humerus bone, affecting the joint and relevant motion Surgical intervention required the removal of the tumor-affected bone and reconstruction of the humerus with a custom prosthesis.

Surgical Planning

A customized humerus implant was designed and developed to ensure precision and functionality. The implant incorporated innovative features tailored to the patient’s unique requirements:

- A lightweight cage structure in the middle shaft to reduce weight while maintaining strength.

- Porous structure at the preserved bone contact points for optimal bone integration.

- Locking screws to ensure stable fixation during and after surgery.

- A mirror-polished spherical head to restore shoulder joint articulation.

- Suture holes for ligament and muscle attachment, facilitating restoration of functionality.

Additionally, cutting guides were provided to achieve precise resection during surgery.

3D-printed, Patient-Specific Solution

The implant was manufactured using metal 3D printing technology in biocompatible titanium grade 5 material, ensuring durability and compatibility with the body. Cutting guides were created using BioMed Amber material, allowing for precise and efficient resection of the affected bone.

Post-op Outcome

The surgery was a resounding success:

- The implant was fixed perfectly into the patient’s body, providing a stable and functional reconstruction of the humerus.

- The patient experienced significant improvement in joint mobility and limb function post-surgery.

This case highlighted the critical role of customized prosthetic solutions and advanced 3D printing technologies in achieving life-changing outcomes for young patients.