Precision Reconstruction in Frontal Defect with Customized PMMA Cranial Implant

By

Dr Ritesh Parmar &

Patient Overview

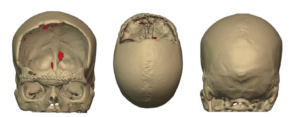

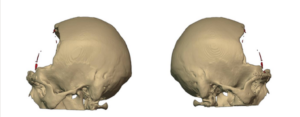

A 25-year-old male presented with a frontal defect and fractured bone pieces reconstructed in a previous surgery. The surgeon requested a customized cranial implant solution tailored to the patient’s unique anatomy to achieve a successful outcome.

Surgical Planning

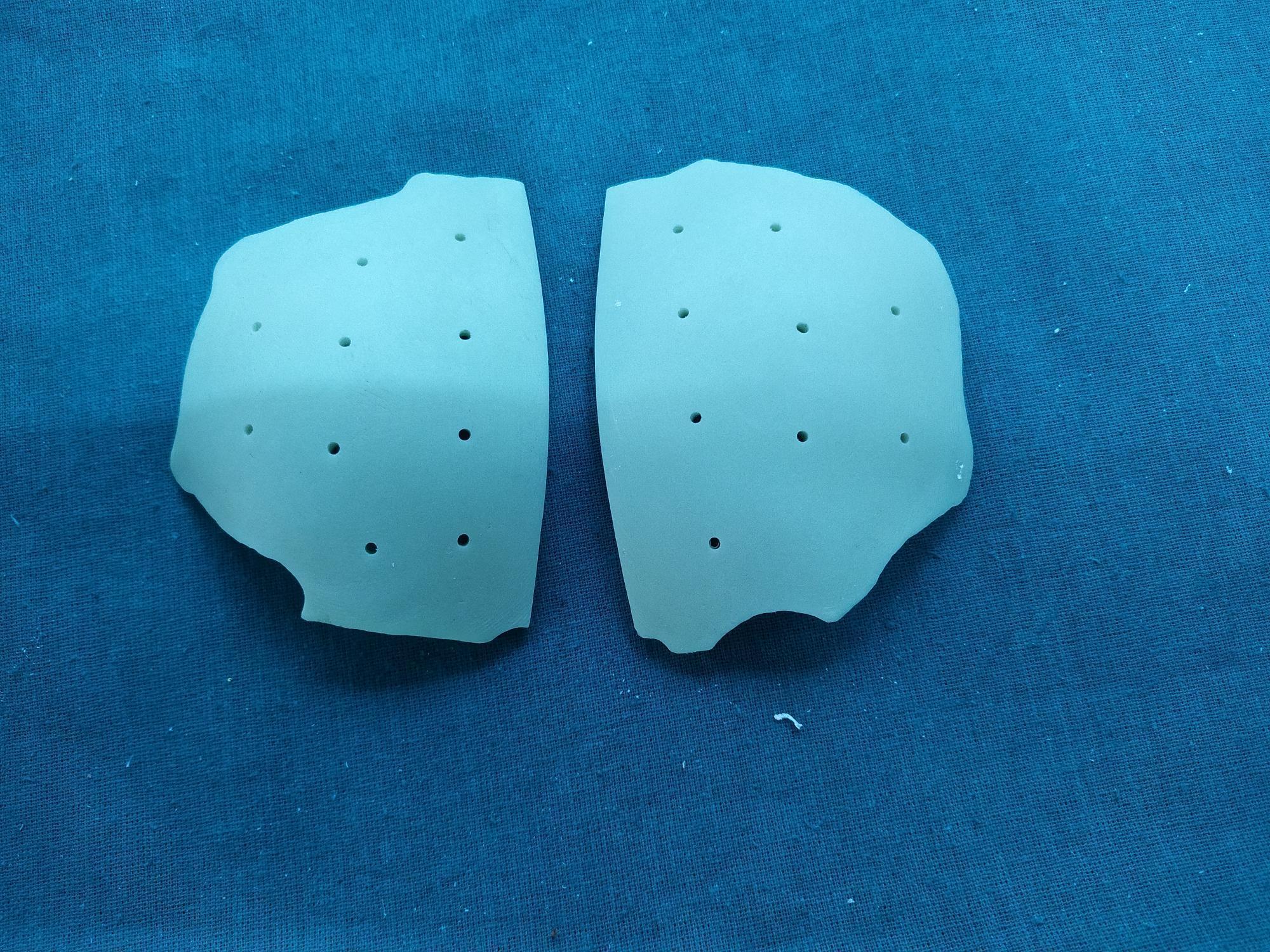

The surgical team meticulously planned the procedure by designing a customized PMMA (Polymethylmethacrylate) cranial plate implant. The implant was crafted to reconstruct the skull’s frontal bone curvature accurately.

Key steps included:

- Designing the plate in two parts for precise alignment with the bone structure.

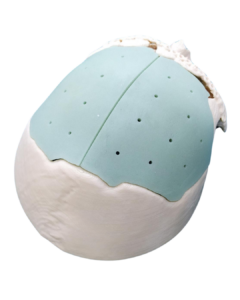

- Utilizing 3D printing technology to create both a skull bone model and a customized PMMA implant to ensure proper fitment and validate the design before surgery.

3D-Printed, Patient-Specific Solution

The use of 3D printing allowed the surgical team to:

- Visualize and evaluate the frontal bone defect.

- Confirm the implant’s fit and curvature to the patient’s anatomy.

- Manufacture a durable, biocompatible PMMA cranial plate, ensuring stability and precision during surgery.

Post-op Outcome

The surgery was highly successful because:

- The cranial plates were fixed securely without any loosening during the procedure.

- The patient demonstrated significant improvement in both functional and cosmetic aspects post-surgery.

The combination of advanced 3D planning and a customized implant underscored the critical role of innovative technology in achieving precise and safe outcomes.

Dr Ritesh Parmar

Brain and Spine Surgeon, Tristar Super speciality Clinic, Vapi, Gujarat