Complex Hip Revision

Discomfort of multiple acetabular revision for the patient is unconceivable. It can also be nightmare for the surgeons if not planned precisely. Sharing this case of 6Oyr/M patient, CT assessment shows ruptured medial wall and significant vertical hardware shift.

There was a lot of artifact around the bone due to metal hardware in the CT images. Such cases need precise segmentation avoiding any artifacts and extracting the 3D model from the scan to provide best visualization experience.

As we move from 2D to 3D, it is amazing to see how our clarity and surgeon’s confidence reaches to the next level. It triggers our mind to approach the problem differently. Our expert surgeon panel helped ensure our planning was on track clearing all doubts around cup positioning. Location of all the screws were re-confirmed and a robust execution plan was prepared.

Our approach is always to Visualize, Plan and then execute

Visualisation:

The first stepping stone to understand and get into the core of the problem is by 3D visualization. For achieving this, we used customized segmentation process overcoming all the challenges like metal artifact, ROI identification issue and preserving the clinically significant regions while creating 3d model. The idea is to provide self-explanatory model and help surgeon to make them visualize the information which usually remain hidden in conventional 2D CT images.

Planning:

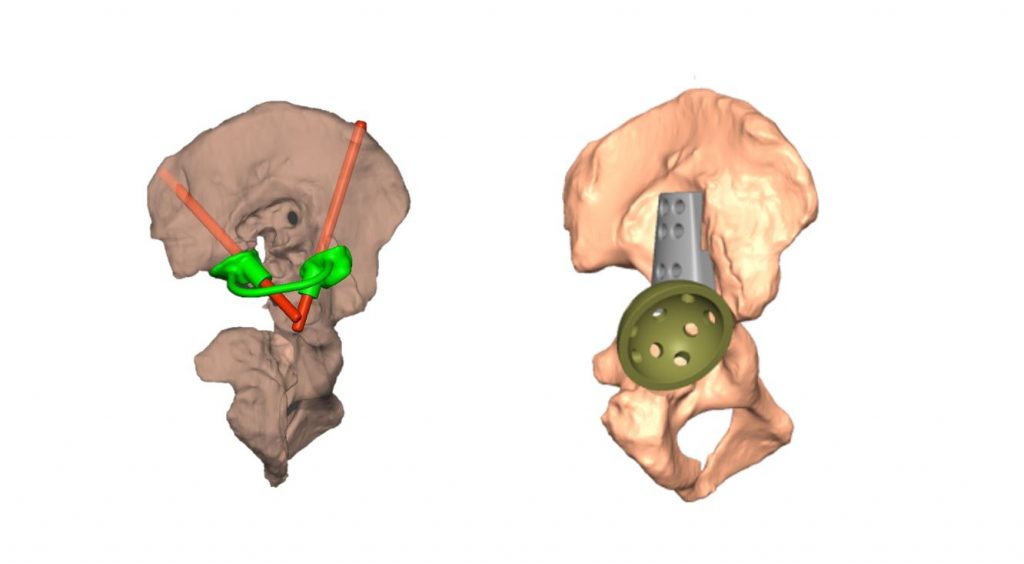

The key element of pre-op planning process is deriving the clear requirement from the surgeon. Below are few design considerations we opted out for this case:

- – Medial wall distorted, and vertical displacement of hardware was very evident. The information helped surgeon to optimize their decision on component placement

- – Mirroring from the healthy side provided the references for the cup placement

- – Performing wall thickness enabled surgeon to identify the denser part of the bone, which eventually was helpful for drilling pin location and optimizing the contact area.

- – Virtual implant positioning enabled surgeon to decide appropriate implant size and ensure its availability in the surgery including necessary additional augments.

- – Identification and creation of the patient specific pin guide for home run screw placement can be of significant value

3D Printing:

To raise clinical value quotient of the 3D printed model, we introduced the concept of Printable Planning Technology. It is the innovative way to engrave the physical model which consists all pre-op information in terms of orientation, measurements, angles and sizing and is a helping hand to the surgeon inside the operation theater.